Driving Sustainability: On the Road

Focussing on large vehicles, with more than 90% of our production supporting pick-up trucks and long-haul heavy-duty commercial vehicles, we make big climate contributions to big volumes of big vehicles.

Commercial Vehicles

The use of CGI enables OEMs to reduce the weight and increase the pressure in commercial vehicle engines. Together, the weight reduction and increased pressure improve the fuel efficiency of the engine, reducing CO2 emissions. Every one million Engine Equivalents of SinterCast-CGI heavy-duty engines contributes to the saving of approximately 200,000 tonnes of CO2 per year (How we Calculate: Read more). In the lead-up to 2027 emissions legislation, heavy duty engines are expected to increase operating pressures by 20% and engine efficiency by 10% to meet the new standards. These requirements continue to drive OEMs toward CGI.

According to the Diesel Technology Forum, from 2007 through 2030, current and new designs of heavy-duty engines, many of them using CGI, will save 550 billion litres of fuel and 1.5 billion tonnes of CO2 compared to previous generation trucks. This CO2 savings is equal to taking every passenger vehicle in the US off of the road for one and half years.

Super-Duty Pick-ups

SinterCast-CGI diesel engines provide 20–30% better fuel economy than the nearest available petrol engine and up to 40% better fuel economy when towing. For the average Super-Duty driver, this improved efficiency translates into fuel savings of approximately 1,000 litres per year (every litre of fuel generates approximately 2.5 kg of CO2). In this high volume sector, the SinterCast technology supports the production of more than 1,000 vehicles every day, providing annual savings of approximately one million tonnes of CO2 per year, every year throughout the life of the vehicle (How we Calculate: Read more). This CO2 saving is enough to fill one million hot air balloons, and equal to taking 250,000 passenger vehicles off the road.

In the Super-Duty sector, SinterCast CGI contributes to the saving of approximately one million tonnes of CO2 per year; equal to taking 250,000 passenger vehicles off the American roads; enough to fill one million hot air balloons

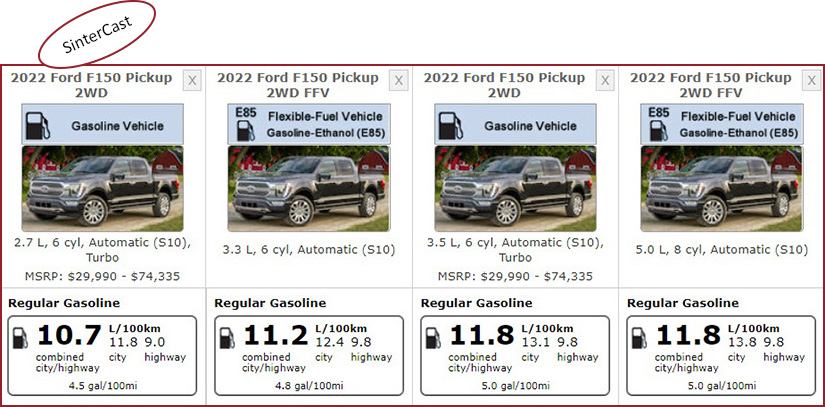

Full-Size Pick-ups

The SinterCast-CGI 2.7 litre V6 petrol engine is the smallest, lightest and most fuel efficient engine option in the Ford F-150. This efficiency has led to the SinterCast-CGI engine becoming the most popular engine in the most popular vehicle in America. On average, the SinterCast-CGI petrol engine consumes one litre per 100 km less fuel than the nearest available engine option. With the production of more than 1,000 engines per day, the SinterCast-CGI engine contributes to the saving of approximately one million tonnes of CO2 per year, every year throughout the life of the vehicle (How we Calculate: Read more).

CGI vs Aluminium

In comparison to aluminum, Compacted Graphite Iron provides advantages related to strength, durability, wear resistance, design freedom, NVH, package size, cost, and manufacturing CO2. Despite these advantages, aluminum cylinder blocks have leveraged weight reduction to make considerable gains in the small, in-line passenger vehicle sector over the last 30 years.

On 28 April 2022, at the Vienna Motor Symposium, Tupy, Ricardo and SinterCast revealed a novel CGI in-line petrol engine concept with the same weight as aluminium. Compatible with biofuels and future net zero fuels, this breakthrough innovation offers the potential for long-term growth opportunities in the small, in-line passenger vehicle sector that accounts for more than 70% of global passenger vehicles, and in hybrid and battery electric range extender applications.

How we Calculate

Commercial Vehicles – Fuel Efficiency: The newest generation of heavy-duty SinterCast-CGI diesel engines provide approximately 8% better fuel efficiency than the previous generation. For a 13 litre engine with annual mileage of 100,000 km and fuel consumption of 25 litres per 100 kilometres, the improved efficiency saves approximately 2,000 litres per year. Every litre of diesel fuel generates approximately 2.5 kg CO2; accordingly, the CO2 saving is approximately 5 tonnes per truck. If one-third of the saving is attributed to the combustion, the improved properties of CGI and the associated weight reduction, this corresponds to a SinterCast contribution of 1.7 tonnes per truck per year. The SinterCast technology currently supports the production of approximately 200,000 heavy-duty vehicles per year, providing annual savings of more than 300,000 tonnes of CO2 per year – throughout the life of the vehicle.

Super-Duty Pick-up Trucks – Fuel Efficiency: SinterCast-CGI diesel engines provide 20-30% better fuel economy than the nearest available petrol engine and up to 40% better fuel economy when towing. For the average Super-Duty driver, travelling 20,000 miles (32,400 km) per year, the improved efficiency saves approximately 1,000 litres per year. Every litre of diesel fuel generates approximately 2.5 kg of CO2. The SinterCast technology supports the production of more than 1,000 Super-Duty vehicles every day, providing annual savings of approximately one million tonnes of CO2 per year – throughout the life of the vehicle.

Ford F-150 Pick-up Truck – Fuel Efficiency: The SinterCast-CGI 2.7 litre V6 petrol engine is the smallest and most fuel efficient engine option in the F-150 lineup, consuming approximately one litre less fuel per 100 kilometres compared to the nearest available engine option. With average driving distance of approximately 12,500 miles (20,000 km) per year, each vehicle saves approximately 0.5 tonnes of CO2 per year. The SinterCast technology currently supports the production of approximately 300,000 F-150 engines per year, providing annual savings of approximately 150,000 tonnes of CO2 per year – throughout the life of the vehicle.