Building our Business

Newton’s First Law: an object at rest will stay at rest unless acted upon by an external force.

CGI was first observed and patented in 1948, but it took more than 50 years for the first series production engine to be launched. Why the remarkably long development cycle? First, CGI is indeed difficult to produce. Second, there was no driver to promote the benefits of the material. SinterCast was the external force that motivated the industry to overcome these hurdles. The introduction of our technology enabled the reliable high volume production of CGI and we have worked tirelessly to educate and motivate the foundry and automotive industries about the benefits of CGI in engine applications. For more than 30 years, we have built our own business. We continue to drive the market opportunity.

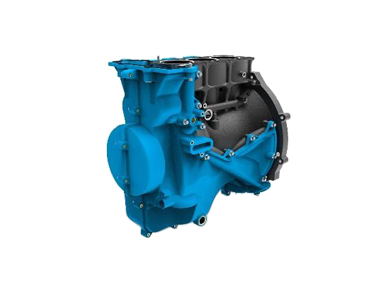

During 2022, together with Tupy and Ricardo, SinterCast introduced a novel concept that re-imagined and re-invented the petrol engine cylinder block. Beginning with a state-of-the art 1.2 litre three-cylinder petrol engine, the team redesigned the cylinder block in CGI to achieve the same weight as the series production aluminium block. The CGI engine required 54% less metal and generated approximately 50% less CO2 during manufacturing. The engine concept can be used in hybrid and battery-electric vehicle range extender applications, and with biofuels, synthetic fuels and other carbon neutral of net-zero CO2 emission fuels. SinterCast is actively engaged in research projects for net-zero CO2 emission engine applications, including the development of hydrogen fuelled commercial vehicle engines.